チェーンステアリングは車両で採用される最も一般的なステアリングシステムの一つです。このシステムは厄介な場合もありますが、...">

あなたの車が左や右に曲がるためには、ステアリングが必要です。そして チェーン ステアリングは、おそらく車両で使用されている最も一般的なステアリングシステムの一つです。扱いが難しい場合もありますが、車が道路上で安全に走行するために非常に重要かつ簡単なものです。このレッスンでは、ラックアンドピニオンステアリングシステムの仕組み、その有用性、どの種類の車両に搭載されているか、一般的な問題のトラブルシューティング方法、そしてこれらのシステムがどのように進化してきたかについて説明します。

ラックアンドピニオンステアリングは、ピニオン(円形の歯車)とラック(平らなバー)を使用しています。運転者がハンドルを切ると、ピニオンが回転し、ラックが左右に移動します。この動作により、車の前輪が運転者が望む方向に旋回します。ラックアンドピニオンステアリング(およびラックアンドピニオンパワーステアリング)は、以前のステアリング方式よりもはるかにシンプルで正確であり、より安全で快適な運転に貢献します。

ラックアンドピニオンステアリングには多くのメリットがあります。その理由の一つは、ホイールを素早く回転させやすいことです。もう一つの理由は、これらのシステムが非常に強固で、他のタイプのステアリングよりもアンダーステアの修理が必要少ないことです。これにより、運転者は車の修理にかかる時間と費用を節約できます。一般のドライバーにとって最も重要なのは、 コンベヤーライン これらのシステムが運転をより快適にし、車をより安全に保つ助けとなることです。

ラックアンドピニオンシステムは、車やトラック、さらには自転車など多くの種類の車両で一般的に使用されています。また、フォークリフトやボートなど、操舵制御が良い車両にも搭載されています。ラックアンドピニオンシステムは、多くの異なる種類の車両や機械で使用できるため、ステアリングの選択肢としてますます主流になっています。

他の機械と同様に、ラックアンドピニオンシステムも修理を必要とする問題が発生することがあります。よくある問題の一つはパワーステアリングフルードの漏れで、これにより操舵が困難になります。定期的な点検(および補充)でこの問題に対処できます。別の問題としては、故障したラックアンドピニオンギアがあり、これにより運転中に振動が発生することがあります。この解決策は、壊れた部品を修理することです。予防的な点検によって、これらの種類の問題を未然に防ぐことができるかもしれません。

そして、今日私たちが持つラックアンドピニオンは、年を重ねて信頼性が向上し、車の他の部分よりも長持ちするように改良されています。これによりハンドリングが大幅に向上します。現代のラックアンドピニオンシステムでは、操舵を支援するために改善された素材と設計が使用されています。現在では、電動パワーステアリングなどの新しい技術がラックアンドピニオンシステムに統合され、特定の条件下でステアリングホイールを回すのを助け、さらに迅速な反応も可能にしています。今後、技術が進歩するにつれて、ラックアンドピニオンシステムはますます正確で信頼性が高まるでしょう。

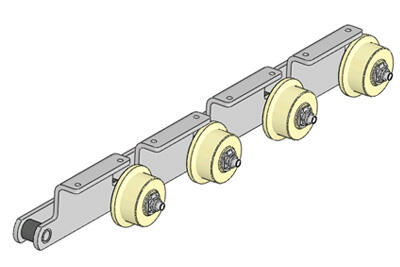

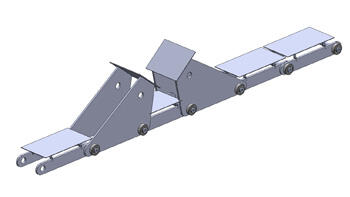

多様な製品ポートフォリオ: 各種コンベアチェーン、PTOシャフト、スプロケット、ギア、カップリング、Vプーリー、ワーム減速機など、幅広い製品をカバーしています。これらの製品は、砂糖、セメント、鉱山、食品、水、木材、自動車、パーム油などの産業で広く使用され、ワンストップの製品ソリューションを提供します。高品質製品の保証: 生産プロセスでは現代的な設備製造と厳格な品質管理措置が採用されています。これにより、製品性能の安定性と信頼性が確保され、使用中の顧客の故障やメンテナンスコストを削減し、生産効率が向上します。

先進的な生産設備:現代の設備を生産プロセスに使用し、製品の高精度かつ高质量な生産を確保し、生産効率と製品の一貫性を向上させ、激しい市場競争における技術的優位性を維持します。技術研究開発能力:長年の業界経験とカスタマイズされた製品開発能力に基づき、一定の技術研究開発チームと能力を持ち、製品設計と生産プロセスを継続的に改善して、製品性能や技術に関する新しい市場のニーズに対応します。

アフターサービスの品質:専門的なエンジニアチームを有し、アフターサービスを提供しています。これにより、製品使用中に発生する問題に対応でき、顧客に技術サポートと解決策を提供し、生産の継続性を確保し、顧客が会社の製品を使用する際の信頼感を高めます。豊富な情報提供:ニュースやブログセクションを通じて、業界知識やFAQを共有します。例えば、チェーンの錆びに関する問題、コンベヤーの一般的な問題とその解決方法、チェーンの品質判断方法、ギアの歯数設計などです。これにより、顧客に貴重な技術情報や購入のガイダンスを提供し、製品や業界のトレンドをよりよく理解できるよう支援し、会社の専門性と業界における顧客への配慮を示します。

豊富な業界経験:2005年に設立され、工場の歴史は2000年までさかのぼり、ギアボックス、チェーン、伝動軸、伝動ライン部品などのさまざまな分野で25年以上の製造専門知識を持っています。これにより、深い産業遺産を蓄積し、多様な生産や市場の課題に更好地に対処できるようになりました。プロフェッショナルなカスタマイズ能力:OEM製品のカスタマイズ開発に焦点を当てており、顧客の特定の要件に基づいて個別生産を行うことができ、市場の多様なニーズに対応しています。市場競争において高い柔軟性と適応力を示しています。優れた国際的評判:顧客への誠実さ、注文に対する高い責任感、そして海外顧客との長期的な協力経験により、同社の製品はヨーロッパ市場で広く人気があります。世界中の顧客の信頼を勝ち取り、ブランドの影響力はさらに拡大しています。

著作権 © 杭州オーシャンインダストリー株式会社 すべての権利を保有